In the realm of modern industry, efficiency and safety are paramount. One area where these two elements converge is in lifting operations, a critical aspect of construction, manufacturing, and logistics. The advent of custom-built electric hoists has revolutionized the way businesses approach heavy lifting, offering solutions tailored to their specific needs and challenges. These innovations not only enhance operational efficiency but also improve safety standards, making them indispensable tools in various industries. Custom-built electric hoists are designed to meet the unique requirements of different applications. Unlike off-the-shelf hoists, which may only partially address specific needs, custom solutions are engineered from the ground up, taking into consideration the load capacity, lifting height, operational environment, and safety standards. This level of customization allows for the creation of hoists that can handle varying weights and sizes, ensuring that businesses can optimize their lifting processes without compromising safety.

One significant advantage of these tailored electric hoists is their ability to integrate advanced technologies. Many custom hoists now feature smart controls, which utilize sensors and automation to enhance lifting precision and reduce human error. These controls can monitor load weight, detect abnormalities, and provide real-time data analytics, allowing operators to make informed decisions. Such innovations lead to streamlined workflows, reducing downtime and increasing overall productivity. Moreover, the safety features in custom-built electric hoists cannot be overstated. With enhanced mechanisms for load monitoring, emergency stop functions, and fail-safe systems, these hoists minimize the risks associated with heavy lifting. The ability to program safety protocols into the hoist’s operation ensures compliance with industry regulations, thereby protecting both workers and equipment. The investment in such customized solutions ultimately pays off by reducing accidents, lowering insurance costs, and improving worker morale.

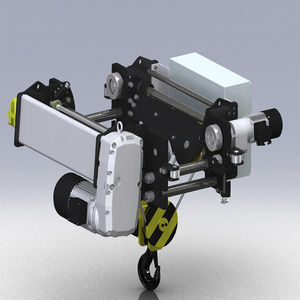

Another critical aspect of custom-built electric hoists is their adaptability to various environments. Whether in a factory with tight spaces, an outdoor construction site, or a specialized facility requiring cleanroom standards, these hoists can be designed to operate effectively. This versatility allows businesses to maintain high efficiency across diverse operations without needing multiple lifting solutions. Additionally, the longevity and reliability of custom electric hoists contribute to their cost-effectiveness. Built with high-quality materials and components, these hoists are designed to withstand the rigors of daily use, leading to lower maintenance costs and less frequent replacements. This durability ensures that companies can rely on their lifting solutions for years, further justifying the initial investment. custom-built polipasto eléctrico de cable represent a transformative approach to lifting operations across various industries. By prioritizing efficiency, safety, and adaptability, these tailored solutions not only optimize workflows but also provide peace of mind. As industries continue to evolve and demand more from their lifting equipment, the adoption of custom electric hoists will undoubtedly play a crucial role in driving operational success and safety standards to new heights.